Proven Tips to Pick the Right Stainless Steel Metric Tubing

Stainless steel metric tubing is a strong, corrosion-resistant tube sized using the metric system. Choosing the right type matters because each one serves astainless steel tubing pan different purpose.

From hydraulic systems and gas flow to food-grade processing, stainless steel metric tubing is everywhere.

It’s trusted for durability, hygiene, and long-lasting performance. But with so many stainless steel metric tubing types, picking the right one can feel confusing.

This quick guide will help you understand whichmetric stainless steel tubing is best for your job, saving you time, money, and costly mistakes. Let’s break it down simply so you can pick smart from the start.

Understanding Stainless Steel Tubing Basics:

Stainless steel stands out because it resists rust and handles pressure. The most common types are 304 and 316 stainless steel metric tubing.

Type 304 is excellent for general use, while 316 is stronger against chemicals and salt, making it perfect for harsh environments.

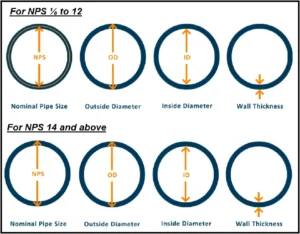

Now, don’t mix tube and pipe. Pipes carry fluids and are measured by their inside diameter. Tubes are used for structures or precision systems and are measured by their outside diameter.

Knowing these basics helps you choose the right stainless steel tubing for your project without overpaying or using the wrong material.

What Does “Metric” Mean in Tubing?

Metric size tubing is measured in millimeters, while imperial tubing uses inches. Think of it like using kilometers vs miles.

Most of the world uses metal tubing in metric sizes because it’s part of the global standard. Understanding metric vs imperial tubing helps avoid sizing mistakes in international projects.

Different Types of Metric Stainless Steel Tubing:

Each tubing type serves a unique role in performance, durability, and appearance. Here’s how they differ and where they work best:

Seamless Tubing

Seamless stainless steel tube has no welds, making it strong and leak-proof. It’s ideal for high-pressure systems like hydraulic lines, fuel injection, and medical tools.

Welded Tubing

Welded stainless steel tubing is made by welding flat steel into a tube shape. It’s cost-effective and perfect for low-pressure tasks like handrails, exhaust systems, and furniture frames.

Annealed Tubing

Heat treatment softens annealed precision metric tubing, allowing it to bend without cracking. It’s commonly used in food equipment, chemical transfer lines, and flexible fluid applications.

Polished Tubing

Polished ss steel tube has a smooth, shiny finish for better hygiene and appearance. It’s ideal for visible installs in kitchens, labs, and architectural designs where cleanliness matters.

Common Applications by Industry:

Seamless stainless steel tubing is trusted across industries for strength, hygiene, and corrosion resistance in critical applications.

Hydraulics

Seamless stainless steel tubing handles high pressure in hydraulic systems like forklifts and construction machinery, ensuring reliable fluid transfer without leaks.

Food Processing

Its corrosion-resistant tubing quality makes it perfect for dairy, beverage lines, and food machinery where cleanliness and safety are essential.

Medical

With its smooth, sterile surface, seamless tubing prevents bacteria buildup in surgical instruments, IV systems, and medical gas lines.

Chemical

Seamless tubing resists harsh chemicals and corrosive fluids in industrial plants, maintaining safety and durability under harsh conditions.

Aerospace

Lightweight yet strong, it supports aircraft fuel, cooling, and hydraulic systems and performs well under extreme temperatures and pressure changes.

304 vs 316 Stainless Steel: Which Should You Choose?

304 is strong and affordable, perfect for general use. 316 offers better corrosion resistance, especially against salt and chemicals, but costs more.

316 stainless steel tubing is the best choice for harsh environments; otherwise, 304 works well and saves money.

Understanding Tubing Size Charts and Wall Thickness:

A clear grasp of the tubing size chart is essential when working with stainless steel metric tubing.

These charts list the tube’s outer diameter (measured in millimeters) alongside its wall thickness options. The outer diameter tells you how wide the tube is, while the wall thickness shows how thick the tube walls are.

Wall thickness is crucial because it directly impacts the tube’s strength, durability, and weight. Thicker walls mean the tube can handle higher pressure and resist damage better, but will also be heavier and less flexible. Thinner walls are lighter and easier to bend but might not withstand as much stress.

Standards like DIN 2391 provide exact dimensions and wall thickness guidelines, ensuring consistency and reliability. This standard is widely used for precision tubing, helping manufacturers and users pick the right size and thickness for their specific application.

Knowing how to read and apply a tubing size chart and understanding wall thickness specifications ensures you select the right tubing that meets performance needs and safety standards without overspending or risking failure.

How to Choose the Right Tubing for Your Project?

Choosing the right stainless steel metric tubing starts with a clear checklist.

First, consider the pressure rating your project requires—will the tubing handle high or low pressure? Next, think about the environment: Is it corrosive, humid, or food-grade? This affects the type of stainless steel and finish you need.

Budget matters, too. Higher-grade tubing, like 316, costs more but lasts longer in harsh conditions.

Also, check which standards apply: DIN vs. ASTM. Each has different specifications and quality levels, so pick the one that fits your industry requirements.

Finally, consider tubing size and wall thickness for strength and fit. Asking these questions will help you select stainless steel tubing that is safe, durable, and cost-effective for your project. A wise choice saves time, money, and future headaches.

Stainless Steel Tubing Standards You Should Know:

Standards like DIN 2391, ASTM, and ISO set clear rules for dimensions, quality, and performance of stainless steel tubing.

DIN and ASTM differ mainly by region and detail—DIN is common in Europe, and ASTM in the US.

Knowing these standards matters when buying industrial stainless steel tubing to ensure safety, compatibility, and reliability in your project’s specific environment and industry.

Cutting and Installing Stainless Steel Metric Tubing:

Learn the essential tools and safety tips, plus best practices for a smooth cutting and installation process.

Tools Needed and Safety Tips

- Use a tube cutter, hacksaw, or angle grinder designed for stainless steel.

- Always wear gloves and eye protection to avoid injury and metal shavings when cutting stainless steel tubing safety stainless steel pipe fittings.

Best Practices

- Measure twice, cut once.

- Deburr edges after cutting to prevent damage or leaks.

- When installing tubing, ensure secure fittings and avoid over-tightening to maintain tubing integrity and performance stainless steel griddle

.

Conclusion:

Before you buy stainless steel tubing in metric sizes, remember these top three: choose the right type for your use, check size and wall thickness, and consider the applicable standards.